Industrial Equipment Maintenance Software

Avoid downtime from equipment breakdowns. Rely on our Industrial Maintenance CRM to keep your operations running smoothly.

Key Features of Our Powerful Industrial Maintenance Management Software

Proper equipment maintenance is vital for industrial operations, as effective management can significantly boost efficiency, safety, and cost savings. Our robust industrial maintenance software is designed to optimize your maintenance workflows and help you achieve these key advantages.

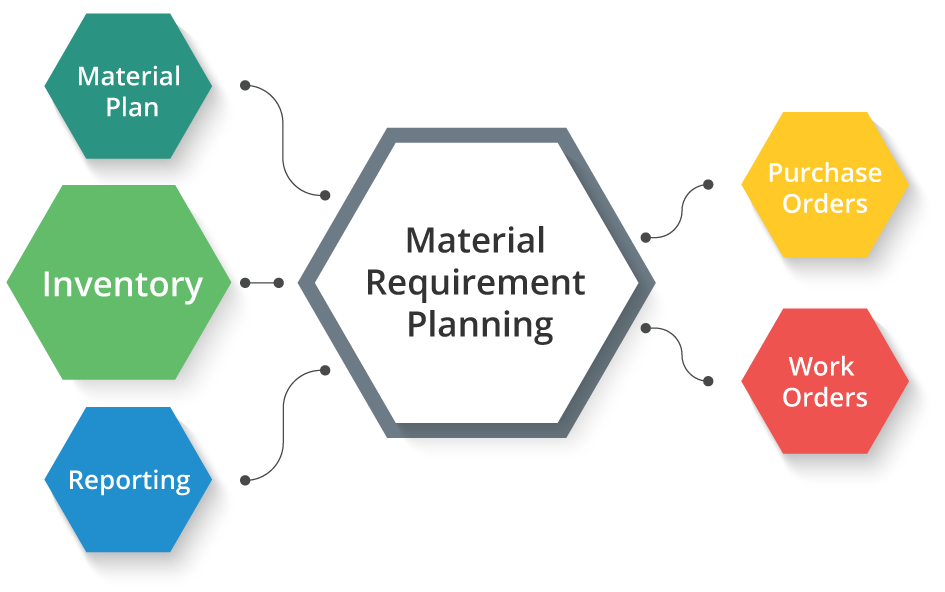

Our construction equipment maintenance software offers a wide range of features, including work order tracking, preventive maintenance planning, asset oversight, inventory tracking, and data-driven reporting. Built to simplify your maintenance operations, it automates routine tasks and provides greater transparency and control over all aspects of maintenance activities.

The Industrial Construction Equipment Maintenance Management Software we offer is fully adaptable to meet your unique needs. Its intuitive interface ensures quick adoption by your team, helping you see results faster. With our system in place, you can increase equipment uptime, lower maintenance expenses, and boost operational productivity—freeing you to concentrate on your core business.

Tools like heavy equipment repair software, such as Quick Assign Service CRM, are indispensable for industries that depend on heavy-duty machinery. This software helps businesses organize and execute repair and maintenance jobs effectively, reducing delays and enhancing overall output.

By delivering a unified platform to manage maintenance schedules, repair histories, and parts inventory, Quick Assign Service CRM supports better decision-making and process efficiency.

Moreover, our heavy equipment maintenance software includes real-time insights and reporting tools, helping you detect and resolve issues before they lead to major failures. This proactive approach not only cuts costs but also ensures your machinery operates at peak performance.

Elevate your maintenance strategy with our advanced industrial maintenance management software and gain a strong edge in your industry by keeping your equipment in top condition.

Key Features of Equipment Maintenance Software

Quick Assign Service CRM has become an indispensable solution for companies across multiple sectors. Its capability to optimize maintenance operations and significantly boost efficiency sets it apart. A standout aspect of Quick Assign Service CRM is its intuitive and user-friendly design. Built for ease of use, the software enables users to move through the system effortlessly, regardless of their technical expertise. Below are some of the key features offered by Heavy Equipment Maintenance Software.

AMC Management

Simplify your Annual Maintenance Contract (AMC) process with our robust CRM Management Software tailored for Manufacturers. Equipped with tools like auto-scheduling and flexible contract templates, our solution lets you handle all your AMC tasks efficiently from a single platform. Stay on top of every service commitment and guarantee on-time maintenance using our easy-to-use and intelligent software.

Scheduling of Field Technician

Our robust Construction Equipment Service Management Software for Manufacturers includes smart technician scheduling capabilities, ensuring your equipment maintenance is timely and efficient. With our Heavy Equipment Repair Software, you can effortlessly allocate and monitor work orders for your field technicians, helping you save both time and resources.

Asset Equipment Tracking

Easily monitor and control your assets and equipment using our advanced equipment tracking functionality. Gain real-time insights into asset performance, plan maintenance activities, and minimize unexpected equipment downtime without hassle. Our industrial maintenance software delivers an all-in-one solution for effective asset management.

Stock Management

Our stock management feature enables manufacturers to monitor inventory levels in real-time. Thanks to our user-friendly system, you can efficiently handle stock quantities, get alerts for low inventory, and create reports to support smarter decision-making. Our software helps you avoid both stockouts and overstocking, ultimately saving time and reducing costs.

Preventive Service Management

Preventive Service Management is a crucial component of our Industrial Maintenance Management Software, designed to keep your equipment maintenance on track. This feature allows you to create recurring maintenance schedules for your machinery, helping you avoid unexpected failures and minimize downtime.

Service Scheduling

Our industrial maintenance software includes a streamlined complaint management system that allows you to monitor and handle customer complaints from a centralized platform. With its intuitive interface, you can quickly pinpoint issues, assign them to the appropriate team members, and follow their status through to resolution.

Complaint Management

Complaint management focuses on improving products and services by actively listening to and addressing customer feedback. While every business strives to avoid negative customer service reviews, even the most reputable brands occasionally receive criticism. Resolving complaints is a vital part of any effective customer service operation.

Field Technician Expense Management

Our industrial equipment maintenance software includes a robust field technician expense management feature that lets you efficiently track and control your technicians' expenses, ensuring they stay within budget and align with company policies. This tool also helps simplify the expense approval process, making it faster and more organized.

Reporting and Analytics

Equipped with advanced analytics and reporting capabilities, our Construction Equipment Maintenance Software delivers critical insights into maintenance planning, equipment downtime, and asset efficiency. These insights empower manufacturers to make informed, data-based decisions and enhance overall operational performance.

Top Heavy Equipment Maintenance Software Service CRM

Heavy equipment maintenance is a critical aspect for industries such as construction, agriculture, mining, and others that rely heavily on machinery for daily operations. Managing maintenance schedules, service history, and repair expenses across an entire fleet can be overwhelming without the proper tools. That’s where our Heavy Equipment Maintenance Software proves invaluable.

Our solution is built to optimize maintenance workflows, automate reports, and boost efficiency by tracking upcoming maintenance tasks and ensuring repairs are completed on time. Through seamless integration with your current systems, our software provides real-time insights into equipment performance and maintenance expenditures, helping you make smarter decisions and enhance operational efficiency.

With our CRM Management Software for Manufacturers, we offer tailored solutions designed to match the unique demands of your industry. By minimizing downtime and enhancing equipment reliability, our platform enables you to reduce costs, increase profitability, and improve overall customer satisfaction.

If you’re aiming to elevate your heavy equipment maintenance strategy, our Heavy Equipment Maintenance CRM Software is your go-to solution.

Main Benefits Of Using Industrial Plant Maintenance Software

Implementing industrial plant maintenance software offers a wide range of benefits for businesses. A primary advantage is its ability to optimize maintenance workflows and enhance overall operational efficiency. With this software, organizations can monitor and manage maintenance activities more efficiently, ensuring that repairs are completed on time and equipment downtime is minimized.

Moreover, many industrial plant maintenance software solutions include predictive maintenance capabilities, helping businesses detect and resolve potential problems before they escalate into serious failures. These are just some of the key benefits of using Software for Industrial Plant Maintenance.

Increased Operational Transparency

Our industrial plant maintenance CRM software provides improved visibility into your maintenance operations. With our CRM management software for manufacturers, you can track equipment maintenance and technician performance in real-time, allowing you to spot potential problems early—before they develop into major issues.

Increase Field Technician Productivity

Boost the productivity of your field technicians using our industrial plant maintenance software. The application enables technicians to access job details remotely and update job progress instantly. With our CRM management software for manufacturers, you can simplify your field workflows and reach greater levels of efficiency.

Improved Customer Satisfaction

Enhanced customer satisfaction is a major advantage of implementing Industrial Plant Maintenance Software and CRM Management Software for Manufacturers. By optimizing maintenance workflows, these software tools allow businesses to deliver prompt and effective service, ensuring a better experience for their customers.

Adapted to meet your industry requirements

Our Industrial Plant Maintenance Software and CRM Management Software for Manufacturers provide precise customization based on your industry-specific requirements. Thanks to the flexible design of our software, you can adapt the system to match your unique needs, promoting a more efficient workflow that boosts productivity and minimizes downtime.

Reduce time and operational costs

Want to optimize your maintenance operations and reduce expenses? Our industrial equipment maintenance software is designed to help you achieve exactly that. Featuring advanced automation tools and customizable workflows, it helps eliminate redundant manual efforts and minimize equipment downtime. Additionally, our mobile application enables field technicians to easily monitor and manage their tasks on the go.

Increase Revenue

The software enables you to understand customer preferences and requirements, allowing you to deliver personalized solutions and boost sales performance. In addition, its reporting and analytics features offer deep insights into your business operations, helping you make data-driven decisions that support revenue growth.

Automate Reports

Improve efficiency by automating report generation with our industrial equipment maintenance software. The system can be custom-tailored to create reports according to your specific needs, including maintenance records, work order summaries, and asset monitoring.

Get rid of Paperwork

Our Industrial Maintenance Software eliminates the hassle of handling paperwork and manual data entry. By switching to a digital platform, you can simplify and organize all maintenance activities and records, removing the reliance on paper-based documentation. This not only saves valuable time but also minimizes errors and delays associated with manual processes.

Equipment Maintenance Management

Maintain optimal performance and extend the lifespan of your equipment with our reliable maintenance management solutions. Simplify your workflows, reduce downtime, and boost productivity with ease.

How to Get Started with Industrial maintenance management software?

Industrial maintenance management CRM software enables manufacturers to optimize their maintenance operations and enhance productivity. If you’re planning to implement this solution in your manufacturing facility, it’s essential to follow a structured approach to ensure a smooth transition.

Start by assessing your existing maintenance workflows and pinpointing the areas where CRM management software for manufacturers and industrial plant maintenance software can bring improvements. Review the features and functionalities of various software options to select the one that aligns best with your operational requirements.

Then, develop a clear strategy for data migration and system deployment. This step may include training your staff, importing current maintenance data, and configuring the software to suit your organization’s specific needs.

Lastly, track the software’s performance over time and make any necessary changes to maximize its value. This includes evaluating maintenance data and KPIs to uncover opportunities for further process enhancements and efficiency gains.

Service CRM Management Software for Manufacturers

Enhance your after-sales service with our powerful Quick Assign Service CRM software, specifically designed for manufacturing businesses. Improve complaint handling and inventory control, automate service appointment scheduling, and elevate customer satisfaction through real-time monitoring and detailed analytics reports. Increase operational efficiency and maintain smooth service workflows with ease!

Effectively oversee heavy equipment repairs, maintenance tasks, and reduce downtime using our advanced Heavy Equipment Maintenance Software. Stay updated with real-time scheduling, track equipment performance, and prolong the life of your machinery effortlessly—and much more!

Why Choose Industrial Maintenance Management Software Service CRM?

Industrial Maintenance Management Software Quick Assign Service CRM delivers a wide range of advantages to businesses across different industries. Since industrial maintenance plays a vital role in the smooth functioning of any manufacturing or production facility, having a reliable maintenance system in place is essential to minimize downtime and ensure seamless operations.

Equipped with a full set of advanced tools and features, Heavy Equipment Maintenance Software helps simplify and optimize maintenance management workflows, improving overall efficiency and boosting productivity.

By centralizing maintenance data and automating routine tasks, the software allows companies to monitor maintenance operations, set up preventive maintenance schedules, and generate detailed reports to support strategic planning and informed decision-making.

Whether you’re a small business or a large enterprise, Quick Assign Service CRM stands out as one of the top choices for industrial maintenance management software in India. Furthermore, Industrial Plant Maintenance Software delivers real-time insights into ongoing maintenance activities, enabling quick issue detection and resolution, which helps reduce costs and avoid unexpected equipment failures.